Check Valves

Swing check valves ensure that the fluid in the pipe can only flow in one direction. The pressure of the fluid on the non-return valve pushes it into the seat and thus prevents backflow. However, a lever with a weight can also be fitted here.

The check valve works completely autonomously and also ensures very good tightness. The swing check must be installed horizontally or vertically upwards in the flow direction of the liquid and is available in nominal sizes from 1/2″ to 36″. A heavy-duty hook can be attached to the larger nominal sizes to optimise installation and make it as simple as possible.

Check valves are “automatic” industrial valves that open with forward flow and close with reverse flow. The pressure of the fluid flowing through a system opens the valve while any reversal of the flow will close the valve. The exact operation depends on the type of check valve mechanism. The most common types of check valves are swing types, piston types or dual plate types.

Types of check valves

Swing type

A swing check valve consists of a valve body, a bonnet and a disc connected by a hinge. The disc swings away from the valve seat to enable a forward flow and returns to the valve seat when the fluid flow is stopped to prevent backflow.

The disc in a swing check valve is unguided because it opens or closes completely. Many plate and seat designs are available to meet the requirements of different applications. The valve enables full, unobstructed flow and closes automatically when pressure decreases. These valves are fully closed when the flow reaches zero to prevent backflow.

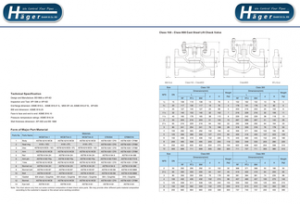

Piston type | Lift type

The seat construction of a check valve is similar to that of a globe valve. The disc usually has the shape of a piston or ball.

Piston type check valves are especially suitable for high pressure applications where flow velocity is high. With this type of valve, the disc is precisely guided and fits perfectly into the damper. Piston type check valves are suitable for installation in horizontal or vertical pipelines with an upward flow. The flow rate for raising the disc must always be below the seat. When the flow occurs, the disc or ball in the guide from the seat is raised by the upward flow pressure. When the flow stops or reverses, the disc or ball is pressed against the seat of the valve by the backflow as well as by gravity.