Gate Valves

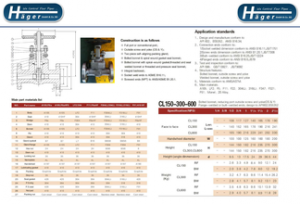

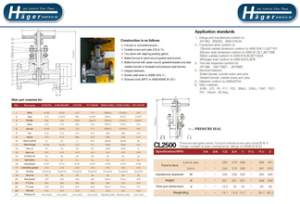

Basic rules for all maintenance procedures: As soon as the valve is closed, maintenance is carried out conveniently. As soon as the valve is closed, maintenance can be carried out conveniently. Alternatives representatives are ball valves, shut-off valves or butterfly valves.

The gate valve for every application profile

Our gate valves can be used in a wide range of applications. Depending on the material and design, they are used for water, gas, oil, steam or other media. At high pressures, we recommend a gate valve with by-pass, as this simplifies operation. This compensates the pressure difference between the two wedge sides and easier operation is achieved. In addition, our valves are also suitable for high temperatures, as certain series have metal sealing. Because of this robust construction, our gate valves are ideally suited for industrial plants, e.g. hot water pipes. Metal-sealing gate valves are also perfectly suited for use with high nominal diameters. Also suitable: For medium with a high solids content.

Nice to know: Since metal-sealing gate valves do not have their own source of ignition, each valve can easily be used in “EX” protected areas.

A must: Full bore, full cross section

The full bore of our gate valves has particular advantages. This means that the normal inner diameter of the connected pipes is not changed by the gate valve, which in turn helps to avoid pressure differences. Especially important: In the case of special media, e.g. waste water, the smooth bore also prevents solids and suspended parts from accumulating. In addition, this also allows this line to be pigged, which saves maintenance costs and time.

Simple operation and numerous options

The gate valve is usually operated by hand or gearbox. Upon request, we also offer our valves with electric or pneumatic actuators. Depending on the application, certain types of actuators can be omitted. A gate valve operated by hand wheel, for instance, is not suitable for underground installation. In the case of larger nominal widths, we also recommend operation by gearbox, as the torques required for operation are quite high. We would be pleased to analyze your application profile with you and assist you in choosing a suitable valve.

A wide range of connection options

Gate valves are equipped with a flange connection by default. If the customer’s pipeline has the same connection flange, the valve can be installed immediately using bolts, screws and gaskets. When it comes to revisions, a flange connection is more beneficial than a gate valve with welding end. As a result, the valve with flange connection can be easily removed from the pipeline by loosening the screws and bolts. However, if the valve has a welding end, the industrial valve must be elaborately removed from the pipeline. However, the flange connection has one disadvantage: It is the weakest link in the chain. The possibility of leaks in the connection can therefore not be ruled out. This is also the reason we offer our customers both options. Whether flange connection or welding end, we would be pleased to offer you our advice!

Did you know ? In the case of cast gate valves, the welding ends can be tested by means of an X-ray test.

Gate valve types

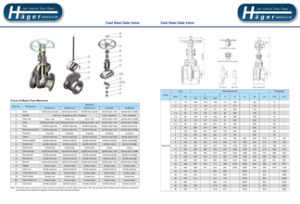

The closing body of the gate valve moves transversely to the flow direction. When fully open, the entire cross-section is available. One advantage that this can have is the low pressure loss. A further advantage in comparison to the shut-off valve is that the gate valve is piggable due to its design. This is not possible with a shut-off valve due to the deflection of the medium. The medium can flow through the gate valve in both directions.

Lower leakage rate thanks to the flexible wedge

The shut-off element has a wedge-shaped design and consists of 2 interconnected plates. There are two different methods. One possibility is to firmly weld the two wedges together by means of a web. A further option is to machine a wedge to such a degree that only one web remains in the middle. The attainable leakage rate here is lower than that of a gate valve with a rigid wedge.

External stem thread

In the case of an external stem thread, the stuffing box packing is located beneath the stem thread of the gate valve. The advantage of this is that the thread is not exposed to the fluid. This design makes it virtually impossible for the stem thread to become snagged. A further advantage over an internal stem thread is the ability to visually inspect the stem immediately.

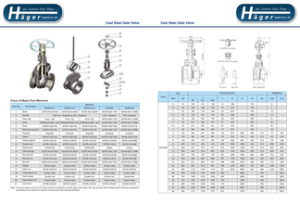

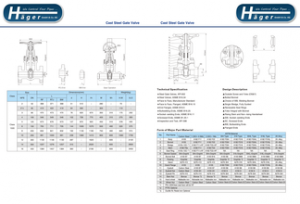

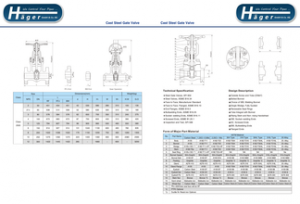

Flat body gate valve or round body gate valve

Due to their larger design, round body gate valves require more space in the pipeline than flat body gate valves and, due to their design, they are longer than flat body gate valves. While round body gate valves are also manufactured for high pressure stages up to PN 160, the flat body gate valve can only be used up to a pressure stage of PN 16. The short design of the flat body gate valve is also used in cases where there is little space in the pipeline. Due to the considerably smaller design, less material is used for production. As a result, the production costs are lower and therefore they are less expensive than round body gate valves.