Globe Valves

Globe valves are different from gate valves. While both are responsible for opening and closing the pipeline, globe valves can be equipped with a regulating cone (throttling cone / regulation disc). This enables the fluid flow to be regulated easily and as required. Another difference between the two valves is that gate valves have a full bore. This is not the case with globe valves.

Globe valves can be installed in any pipeline. These valves are used to regulate liquids or similar substances in the pipeline. Maintenance work can also be carried out on a pipeline by completely closing globe valves using the handwheel.

All globe valves can be equipped with a by-pass valve for an extra charge. This balances the pressure on both sides and, consequently, facilitates operation.

Types

In the case of globe valves, the housing is located in the deflected fluid flow. This results in a considerable loss of pressure, even when the globe valve is fully open. This feature is used to reduce pressure by designing the shut-off body as a throttling cone. A cone with a predefined characteristic is also known as a regulating cone. Because of their design, globe valves have a predetermined flow direction. This direction is usually indicated by an arrow on the valve body. Here, the fluid flow presses against the cone from below. As a result, the pressure loss is within acceptable limits and the stuffing box packing is not under pressure when closed. Many versions also have a back seal or back seat. When open, this seals the stuffing box packing and at the same time relieves the load.

At higher pressures, the reverse flow direction is often allowed, which supports the sealing force when closing. Although the force required here is much higher, this force can be reduced by means of a gear.

Globe valve or gate valve

Gate valves are preferred in pipelines larger than 3 inches, as globe valves that are larger than 3 inches no longer seal safely when the pressure is acting under the valve cone. If the pressure is above the cone, the valve can only be opened after a relief valve has been actuated. Gate valves, however, allow smooth flow. Globe valves divert the fluid flow.

Stellite hardfacing

For high pressures and temperatures as well as special applications, globe valves are equipped with wear-resistant sealing surfaces. A stellite alloy is used as the material. Stellite is very hard and can only be machined by grinding. Regrinding is possible by dismantling the bonnet, stem and cone. It is therefore not necessary to remove and dismantle the industrial valve.

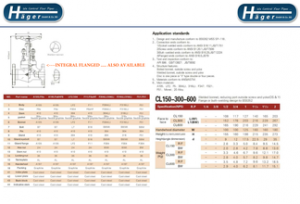

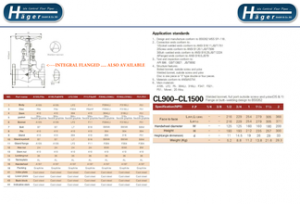

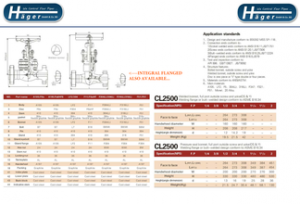

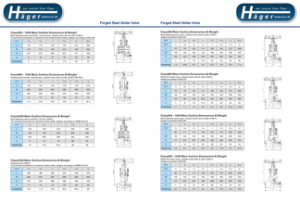

Forged small globe valve

When forged steel globe valves are used, piping can be completely closed or opened, making it easy to perform piping maintenance with the valve closed. One special advantage of globe valves with additionally installed regulating cone is that the medium in the pipeline can be regulated.

Globe valves are equipped with a metal seal and are therefore also suitable for high temperatures. Each valve can be upgraded with a so-called build-up weld (stellite) at an extra charge. This clearly extends the service life of this industrial valve. All valves are available with flange connection, weld-in end or weld-on end. Body material in steel and stainless steel. For high pressure ratings, we recommend a pressure seal design. This self-sealing system reduces possible leaks. All metal sealing globe valves do not have their own ignition source and are therefore also suitable for use in protected areas.

- ATEX Declaration

- NACE Declaration

- RF ASME B16.5, weld end

- TA LUFT

- Regulating cone